The Ultimate Guide To Roar Solutions

The Ultimate Guide To Roar Solutions

Blog Article

The Greatest Guide To Roar Solutions

Table of ContentsThe smart Trick of Roar Solutions That Nobody is DiscussingAll About Roar SolutionsHow Roar Solutions can Save You Time, Stress, and Money.

In such an atmosphere a fire or surge is feasible when 3 standard problems are satisfied. This is usually referred to as the "unsafe area" or "combustion" triangle. In order to shield setups from a potential surge an approach of evaluating and classifying a potentially unsafe location is called for. The function of this is to make sure the proper option and setup of equipment to inevitably stop an explosion and to guarantee safety of life.

(https://www.dreamstime.com/thomascarrillo4740_info)

No tools should be installed where the surface temperature level of the tools is above the ignition temperature level of the given hazard. Below are some typical dirt dangerous and their minimum ignition temperature level. Coal Dirt 380C 225C Polythene 420C (thaws) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dust 510C 300C Phenolic Resin 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Soot 810C 570C The probability of the threat being existing in a concentration high sufficient to create an ignition will certainly differ from place to location.

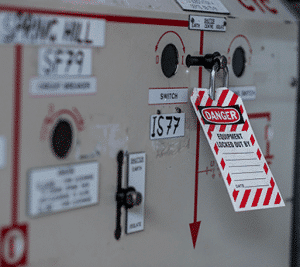

Unsafe area electrical equipment perhaps created for usage in higher ambient temperatures. Field Repair By Authorised Personnel: Challenging testing may not be called for however certain treatments may need to be complied with in order for the tools to preserve its third party score. Each piece of tools with an unsafe ranking must be examined independently.

The Buzz on Roar Solutions

The equipment register is a comprehensive data source of devices records that consists of a minimum collection of fields to identify each thing's area, technical parameters, Ex classification, age, and environmental information. The proportion of Detailed to Shut assessments will be figured out by the Tools Threat, which is examined based on ignition risk (the probability of a source of ignition versus the chance of a flammable atmosphere )and the hazardous location classification

( Zone 0Area 1, or 2). Implementing a durable Risk-Based Assessment( RBI )method is vital for making sure compliance and safety in taking care of Electric Equipment in Hazardous Locations( EEHA).

A Biased View of Roar Solutions

In regards to eruptive danger, an unsafe location is a setting in which an explosive atmosphere exists (or may be anticipated to be present) in amounts that call for unique safety measures for the construction, installment and usage of devices. electrical refresher course. In this post we check out the challenges dealt with in the workplace, the threat control measures, and the needed expertises to function securely

These substances can, in specific problems, form explosive atmospheres and these can have significant and terrible repercussions. Most of us are acquainted with the fire triangular remove any one of the 3 elements and the fire can not take place, yet what does this mean in the context of dangerous areas?

In many instances, we can do little about the levels of oxygen airborne, yet we can have substantial influence on resources of ignition, for instance electrical tools. Dangerous locations are recorded on the unsafe location category illustration and are recognized on-site by the triangular "EX-SPOUSE" indicator. Here, among various other crucial details, areas are divided into 3 kinds depending on the risk, the probability and period that an explosive ambience will certainly exist; Area 0 or 20 is considered the most unsafe and Zone 2 or 22 is regarded the least.

Report this page